The Innisfil of yesteryear was predominantly agricultural. But just because farms were largely put to bed once the landscape was covered in white doesn’t mean farmers sat idle. Far from it. As much as they may have wanted to huddle in their homes until the spring thaw, there was work to be done, important tasks to perform. Among these labours was the harvesting of ice from frozen Lake Simcoe.

The primary method of refrigeration in the 19th and first half of the 20th century, before refrigerators ran by electricity, came from ice painstakingly cut from the lakes and ponds. Not only was the harvested ice used for personal use, but it was vital for the operation of butcheries and restaurants.

Lake Simcoe ice was considered unusually pure and so several large companies that sold ice to Toronto and cities in the United States set up shop on the lake’s shores. The largest were the Lake Simcoe Ice Company and Belle Ewart Ice Company, which took advantage of a pre-existing railroad spur line running right down to the water to efficient ship rail car after railroad of ice to points all over the Eastern Seaboard.

These large companies collectively employed several hundred men. Many others ventured out on the ice with saw and pike to harvest ice on a smaller scale, such as for local stores and the many summer tourist hotels, camps, and dance halls popping up in Innisfil. Sodas had to be kept cold for dancers, the ice boxes in tourist cabins needed filling, and resorts had to keep food fresh. Supplying such local needs offered local farmers welcome additional income over the winter months.

Locals and wholesale operations were not the only interested parties behind ice harvesting. Railways needed vast stores of ice to cool box cars for the shipment of fruit, vegetables, and meat. They too employed Innisfil men on ice-harvesting crews.

Harvesting began in earnest once the ice had reached 10 to 20 inches in thickness which, in a typical year, occurred in early January. It was then a mad dash to bring in the yearly quota before the ice began to melt in March.

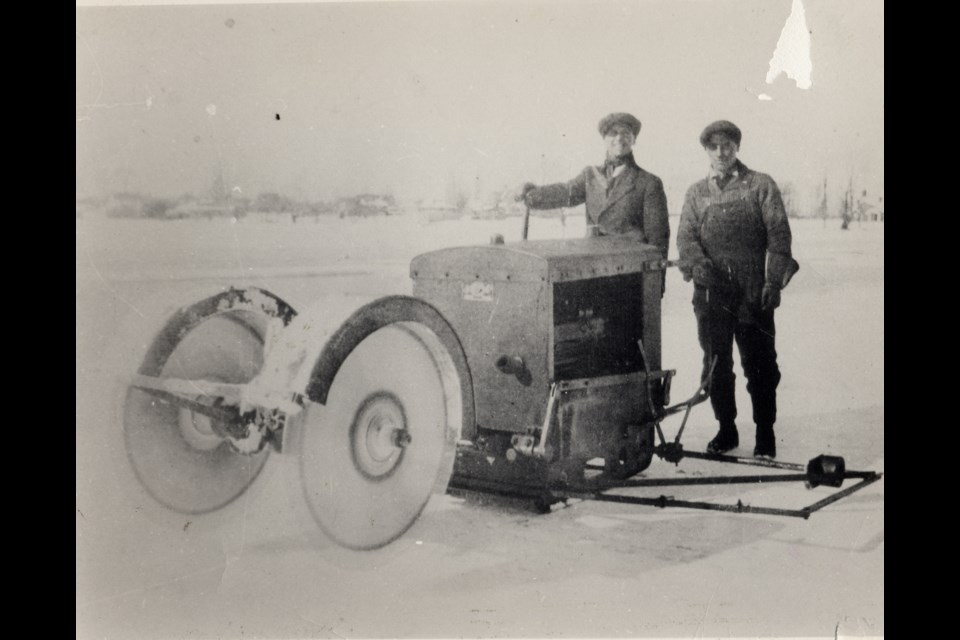

The process of harvesting ice began by removing snow from the lake’s frozen surface with horse-drawn plows. At the point, the outlines of blocks were marked with charcoal. Often, a horse team would run a plow over the lines, etching deep grooves that would ease the process of sawing. Initially the ice was cut using hand saws, but later huge powered circular saws took over. Blocks were brought to shore through channels of open water cut into the ice and guided by men with pike poles. The blocks, often weighing over 100 pounds, were then pulled from the water using a jack ladder system like that used in sawmill and stored in an ice house.

By the 1920s artificial ice began to supplant natural ice. The harvest on Lake Simcoe continued for a few more decades, but slowly melting away with each passing year.

If you have memories of photos of the ice harvest, I’d love to hear from you. I can be reached at [email protected]